Top 1 Turnkey SMT Line Solutions Expert in China

Comprehensive SMT Plant Solutions

Our Services for SMT Lines

Turnkey SMT Line Construction

Mixed & Flexible SMT Lines

High-Speed Mass Production Lines

Prototype & Small-Batch Lines

Spare Parts & Accessories Supply

Training & After-Sales Support

Our Product Range for SMT Lines Solution

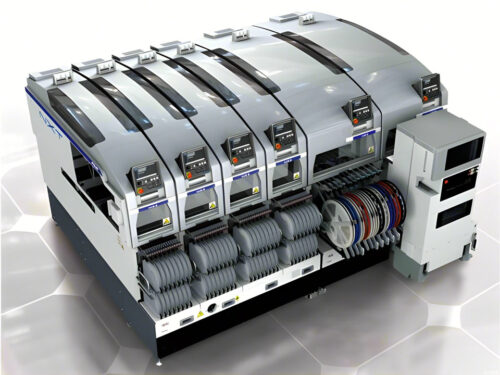

Pick and Place Machines

High-speed, high-accuracy SMT mounters with smart feeders and vision; place 0201–odd-form parts; Industry 4.0 traceability.

Reflow Ovens

Lead-free multi-zone ovens with precise thermal control, nitrogen options, and SPC profiling for stable, low-void solder joints.

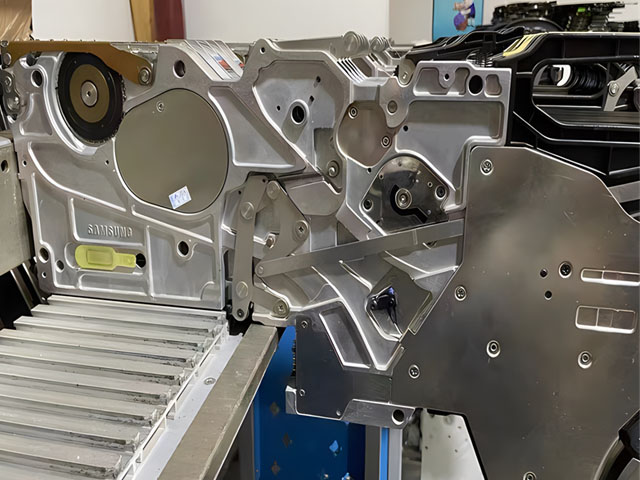

SMT Feeder

Tape, tray, and tube feeders for major brands; quick-change, smart ID, and steady part supply to cut changeover time and boost uptime.

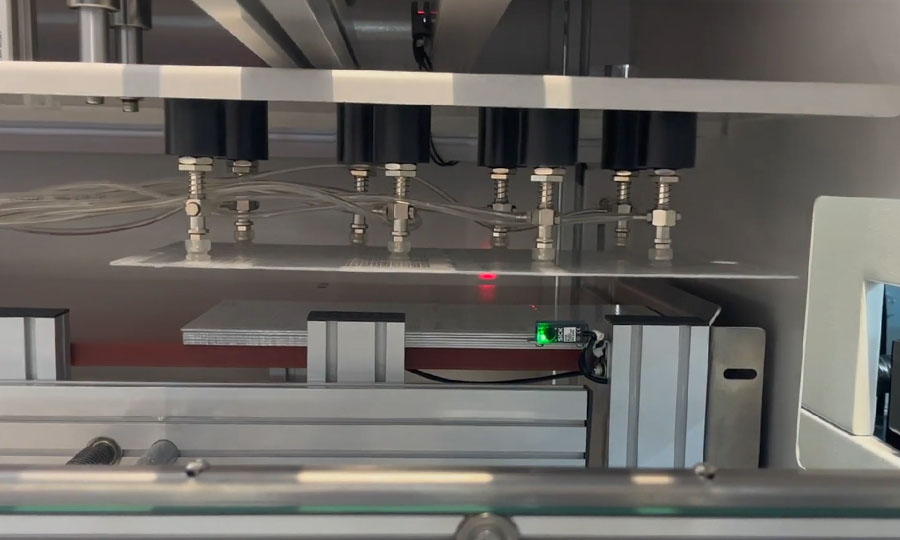

Solder Paste Printer

Precision stencil printers with vision alignment and auto paste control; consistent, repeatable deposits for fine-pitch pads.

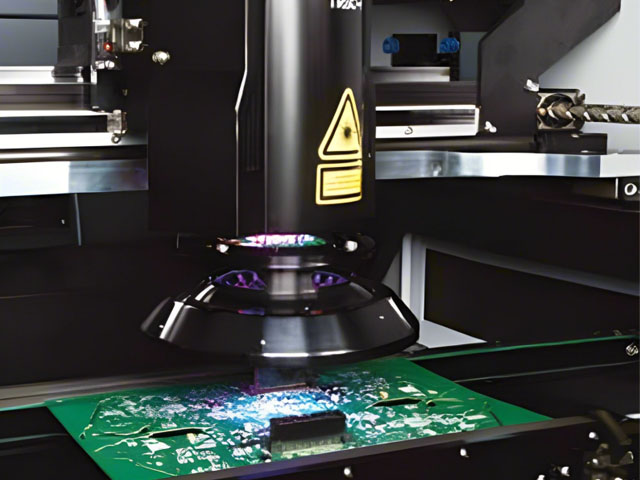

SMT Inspection System

2D/3D AOI and SPI plus inline X-ray to detect paste, placement, and solder defects; boost first-pass yield and traceability.

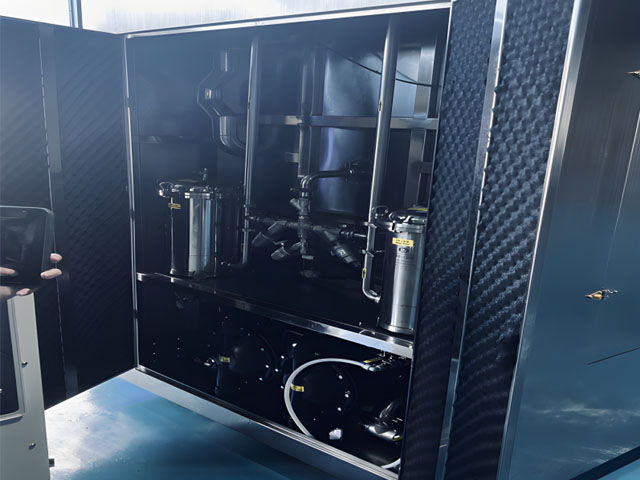

SMT Cleaning Machines

Inline/batch PCB and stencil cleaners—DI water, ultrasonic, or dry-ice—to remove flux/residue and improve reliability.

PCBA Coating Machines

Automated conformal coating with selective spray, film, or jet valves; uniform protection from moisture, dust, corrosion.

PCBA Cutting Machines

Router, laser, and knife depaneling systems that minimize stress and burrs while delivering fast, precise PCB separation.

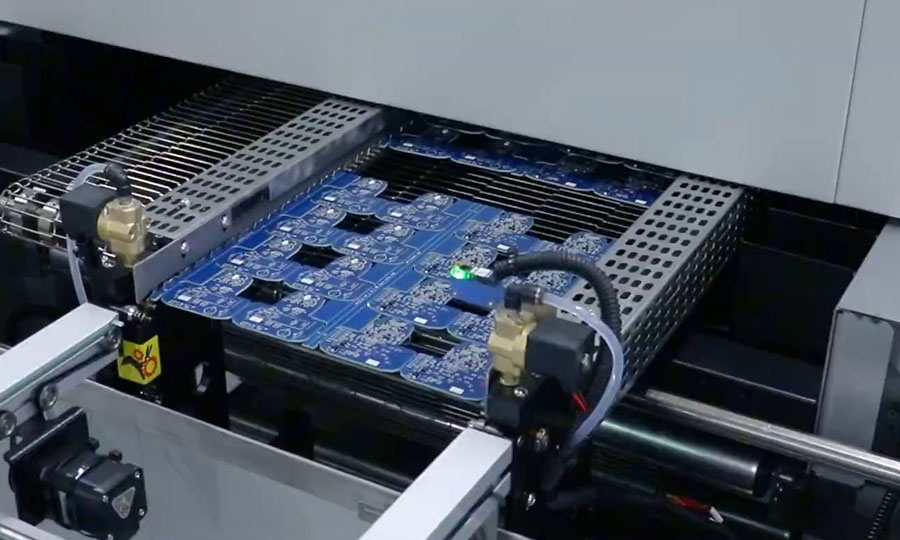

PCB Handling Machines

Loaders, unloaders, buffers, and conveyors to move boards safely, balance takt time, and integrate with any SMT line.

Laser Cutting Machines

High-precision laser systems for depaneling and stencil cutting; clean edges, tight tolerances, minimal mechanical stress.

Reflow Thermal Profiler

K-type profilers and software capture soak, reflow, and peak data to validate oven profiles and ensure compliance.

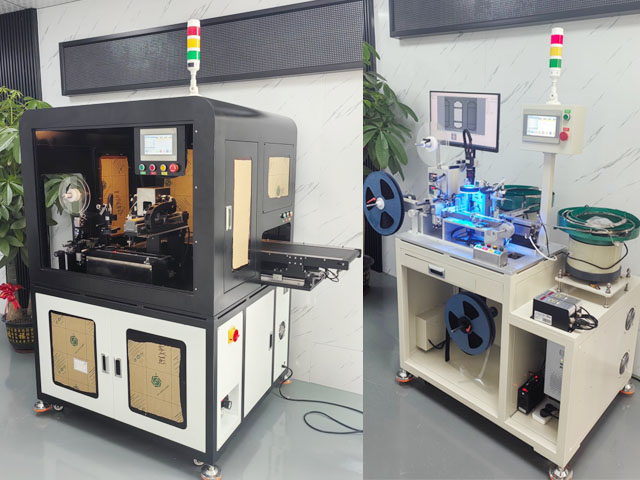

SMD Taping Machines

Automatic taping and reeling for SMD packaging; consistent sealing and labeling for safe logistics and MSL control.

Soldering Robot

Multi-axis robotic soldering with vision, tip cleaning, and stable temperature control for repeatable through-hole joints.

SMT Nozzle

Durable nozzles for Fuji, Juki, Yamaha, Panasonic, and more; optimized suction for tiny chips through complex odd-form parts.

SMT Consumables

Stencils, pastes, adhesives, reels, wipes, and ESD items—everything needed to keep your SMT production line running.

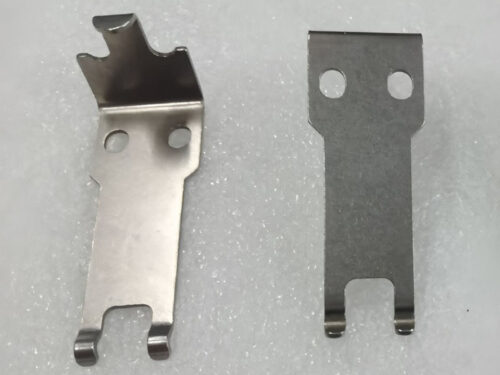

Selective Wave Solder Machine Nozzle

Precision titanium/stainless nozzles; stable flow, anti-oxidation design, easy maintenance.

SMT Grease

High-performance lubricants for rails, bearings, and feeders; low outgassing, wide temperature range, long service life.

SMT Trolley

ESD-safe trolleys for reels, feeders, and PCBs; sturdy frames, smooth casters, organized storage for factory floors.

ESD Ionizing Air Blower

Benchtop ionizers neutralize static on PCBs and work areas; fast decay, balanced ions, cleanroom-ready filters.

Why Choose Meraif as Your Partner on SMT Solution

We combine extensive experience, a customer-focused approach, and a global reach: our clients span North & South America, Europe, Asia, Africa and beyond.

Key advantages of choosing Meraif include:

Over 20 years designing and building SMT factories. Our team’s deep

technical expertise helps us solve even the toughest manufacturing challenges.

We handle every aspect of your project, from consultation and layout

design to equipment installation, calibration, and training . You get a fully integrated SMT line without having to coordinate multiple vendors.

Meraif’s service network and logistics support customers worldwide . We understand international regulations and have multilingual support to serve factories in Europe, the Americas, Southeast and Central Asia, South America, and more.

We emphasize long-term relationships and flexibility. Like Smartlink-SMT, we see ourselves as your partner, not just a supplier. We listen to your needs and tailor our solutions accordingly.

Quality control is built in at every step. We follow strict procedures to ensure machines perform reliably. Each line is fully tested before delivery.

Every SMT line is customized. As iTech notes, we configure the line

based on your board design, throughput and budget . Whether you need a modular multiproduct line or a high-volume dedicated line, we build it for easy upgrades and Industry 4.0 readiness.

Popular Configurations of SMT Lines

-

Splice Cover Tape Extenders Supplier for SMT Production Lines

-

MF-HX5331S Soldering Robot OEM Manufacturer Factory Supply

-

Full Inspection Machine After Taping OEM Manufacturer

-

High cost performance LHL-X100-4 Grease Manufacturer

-

SMT Finger Titanium Steel Material Manufacturer Factory Supply

-

Original KIC START2 6-Channel Thermal Profiler Supplier

-

DEK NeoHorizon 3D Printer Manufacturer High-Precision Printing

-

FUJI NXT-II Pick & Place Machine Manufacturer High-Precision

-

JT CFO Reflow Oven Advanced SMT Equipment Wholesale Factory

-

High-Precision Yamaha YRM10 Pick and Place Machine Supplier

-

DEK Horizon 03ix Printer Manufacturer for Precision Printing

-

Wave Soldering Finger Manufacturer High-Quality Supply

-

MPO(1)-7 Grease Supplier Reliable Industrial Lubrication

-

MG70 Grease Gun Manufacturer Durable High-Performance Tool

-

Electronic PCBA Cleaning Machine Supplier Manufacturers

-

Ionizer Fan SL-002 Manufacturer for ESD Control and Air Purification

Exhibition Experience & Partners

Powering Electronics Manufacturing Across Global Industries

Consumer Electronics

Industrial Automation

Telecommunications

Medical Devicesv