| Specification | Details |

|---|---|

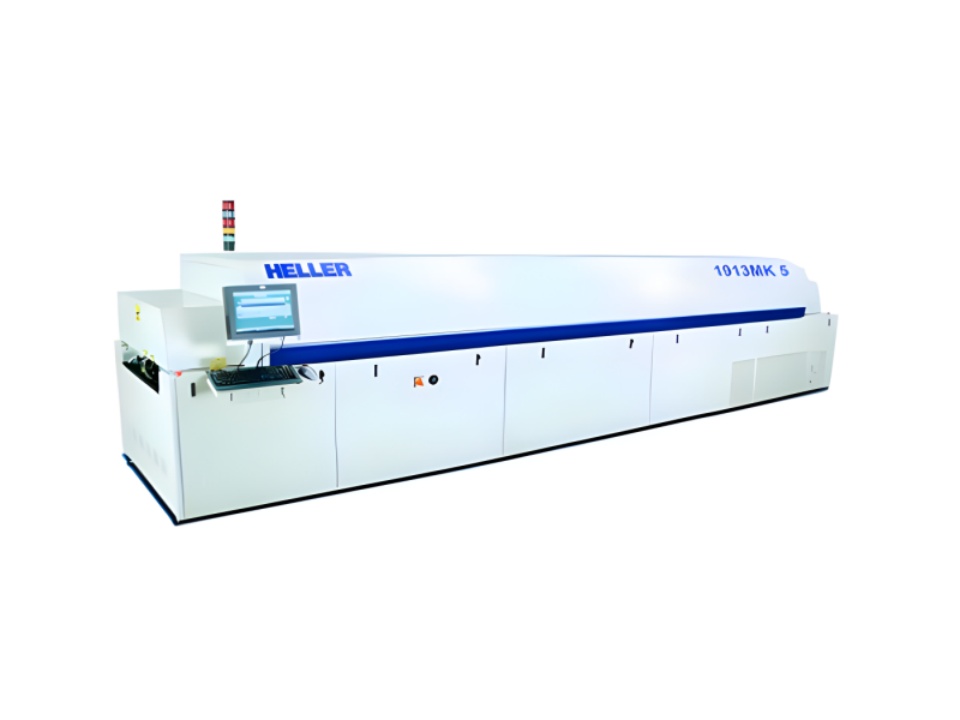

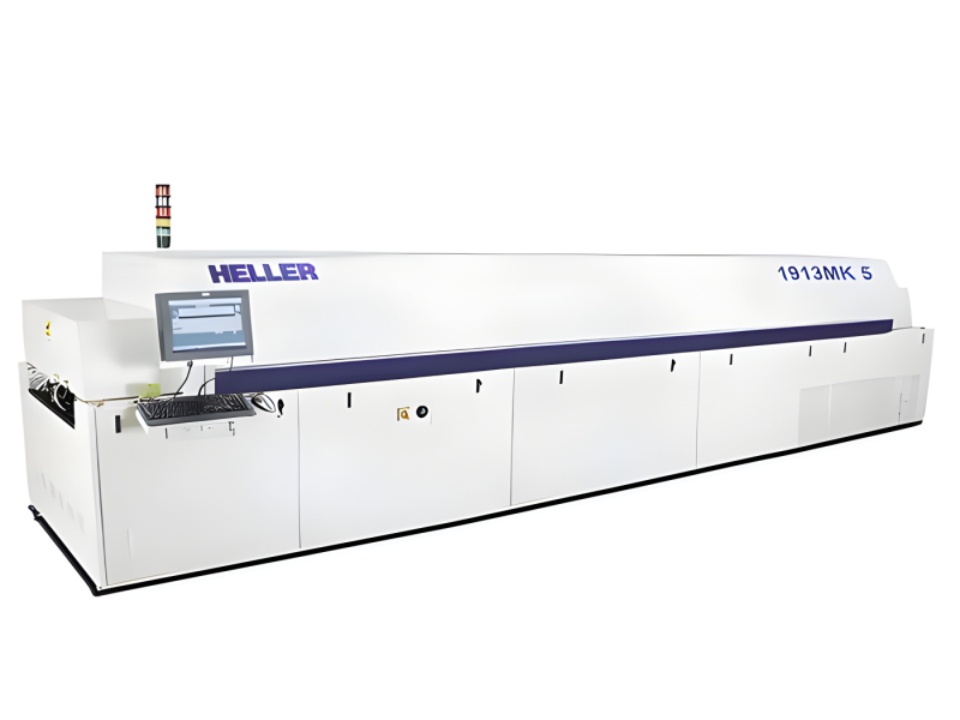

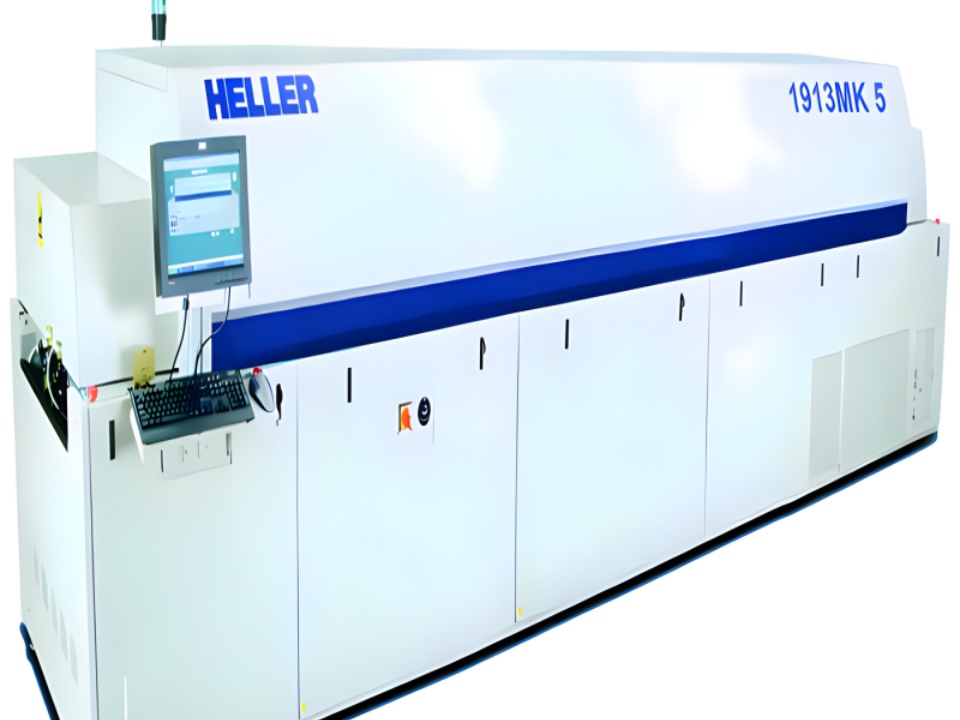

| Model | HELLER 1913 MK5 |

| Machine Type | Advanced Solder Reflow Oven |

| Heating Zones | 13 top / 13 bottom |

| Cooling Zones | 3 |

| Max PCB Width | 500 mm |

| Conveyor Direction | Left to Right / Right to Left (selectable) |

| Temperature Control | ±1 °C precision |

| Max Temperature | Up to 350 °C |

| Heating Method | Forced Convection |

| Nitrogen Capability | Optional |

| Energy Efficiency | Reduced power consumption with heat recovery |

| Warm-Up Time | < 20 minutes |

| Power Supply | 380–480V, 3-phase |

| Machine Dimensions | 6,950 × 1,500 × 1,450 mm |

| Machine Weight | Approx. 2,800 kg |

| Applications | SMT reflow soldering, mass electronics production |

Original HELLER 1913 MK5 Advanced Solder Reflow Oven Exporter

Original HELLER 1913 MK5 Advanced Solder Reflow Oven Exporter provides high-efficiency thermal processing with energy savings, precise temperature control, and reliable performance. Designed for SMT mass production, it ensures consistent soldering quality and reduced operational costs.