Key Features

- Super-fast core cycle times: 5s (TQ) / 6.5s (TQ L)

- Wet-printing accuracy: ±17.0 μm @ 2 cpk

- Machine accuracy: ±12.5 μm @ 2.0 cmk (6σ)

- Compact footprint: 1.3 – 1.95 m²

- Fiber-optic NuMotion controllers with unique 3-stage transport

- Off-belt printing & innovative clamping systems

- Automatic Smart Pin Support & Dual Access Cover for non-stop operation

- Seamless integration with SPI, MES, ERP, AIV fleet management

- Supports IPC-HERMES-9852 and IPC-CFX standards

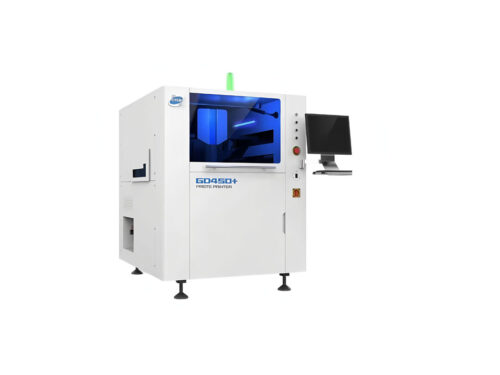

Technical Specifications

| Specification | DEK TQ | DEK TQ L |

|---|---|---|

| Core Cycle Time (CCT) | 5 sec | 6.5 sec |

| Wet-printing Accuracy | ±17.0 μm @ 2 cpk | ±17.0 μm @ 2 cpk |

| Machine Accuracy | ±12.5 μm @ 2.0 cmk (6σ) | ±12.5 μm @ 2.0 cmk (6σ) |

| Max. Print Area | 400 × 400 mm (1-stage) | 560 × 510 mm (single stage) |

| 560 × 400 mm (All Purpose Clamp) | 600 × 510 mm (single stage) | |

| Min. Substrate Size | 50 × 50 mm | 50 × 50 mm |

| Max. Substrate Size | 250 × 400 mm (3-stage) | 600 × 510 mm (single stage) |

| Controller | NuMotion controller | NuMotion controller |

| Axis Drive | Linear drive with encoders | Linear drive with encoders |

| Squeegee Pressure Control | Software-controlled, closed-loop | Software-controlled, closed-loop |

| Dimensions (L × W × H) | 1000 × 1300 × 1600 mm | 1300 × 1500 × 1600 mm |

Smart Automation

- Average 8+ hours runtime without operator assist

- Closed-loop SPI integration ensures printing efficiency

- Automatic stencil positioning with drip tray

- Full compliance with Smart Factory communication standards

Applications

- High-speed, high-precision PCB assembly

- Advanced SMT production lines

- Smart factory automation environments