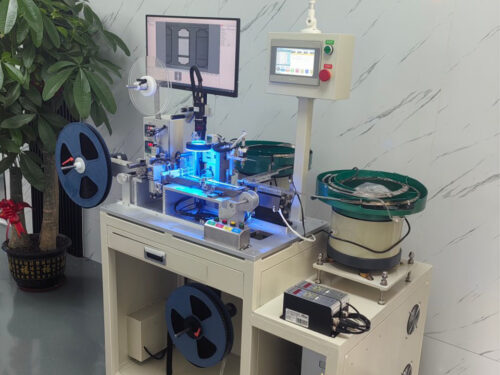

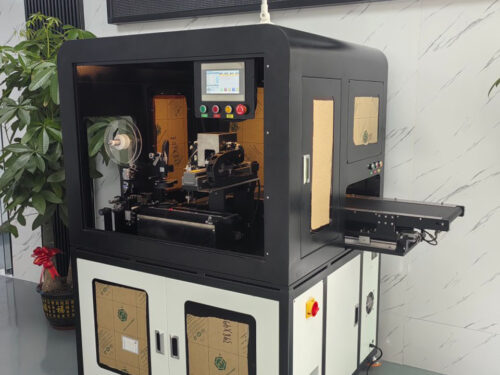

Key Features

- High-speed full inspection after taping process

- Advanced vision system for accurate defect detection

- Automatic sorting for pass/fail results

- Supports multiple component sizes and tape formats

- User-friendly interface with intuitive control

- Compact design for seamless integration into production line

Technical Specifications

| Item | Specification |

|---|---|

| Inspection Type | 100% full inspection after taping |

| Detection Method | High-resolution vision system |

| Component Size Range | Customizable (standard IC, SMD, etc.) |

| Tape Width Compatibility | 8mm–56mm (optional customization) |

| Inspection Speed | Up to 30,000 units/hour (model dependent) |

| Defect Detection | Missing, misplacement, orientation, defects |

| Sorting Method | Automatic NG/OK binning |

| Control System | PLC + Touchscreen HMI |

| Data Output | SPC data, traceability reports |

| Power Supply | AC 220V, 50/60Hz |

| Machine Dimensions | Approx. 1200mm × 800mm × 1600mm |

| Weight | ~450 kg |

Applications

- Post-taping inspection for semiconductors and SMDs

- Quality control in electronic component packaging

- OEM/ODM production lines requiring high precision