| Feature | Details |

|---|---|

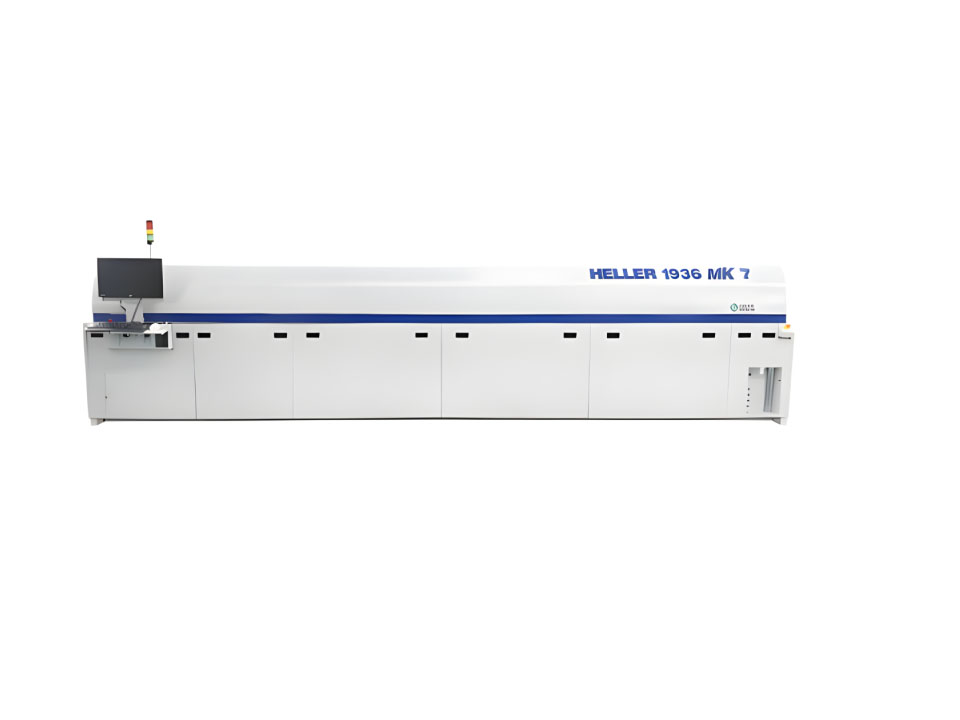

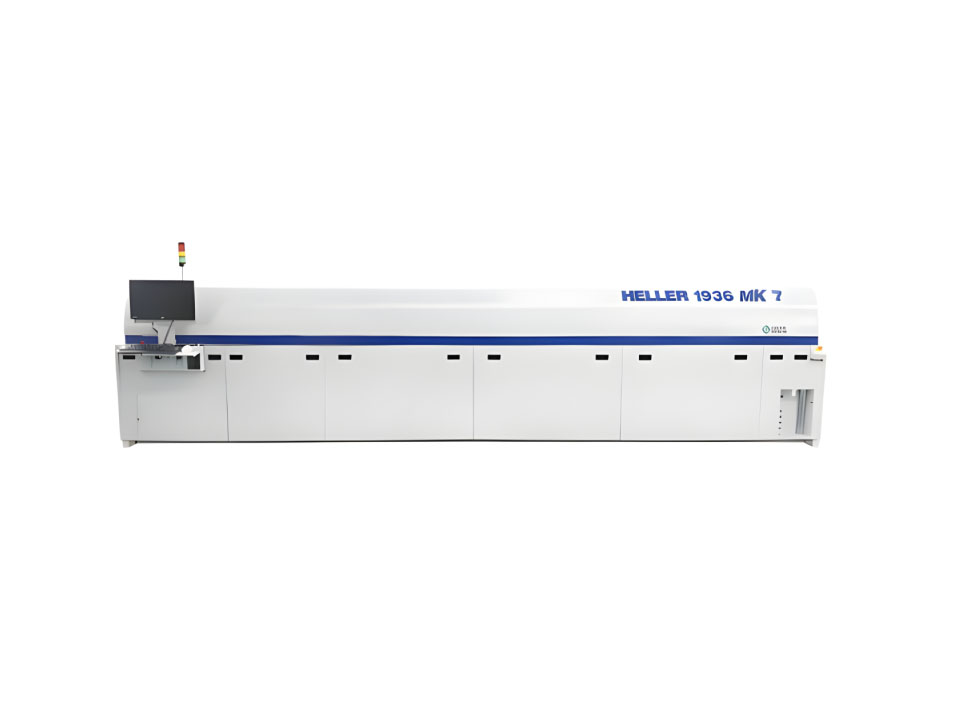

| Model | HELLER 1936 MK7 |

| Type | Solder Reflow Oven |

| Application | SMT PCB Assembly |

| Heating Zones | 8–10 top & bottom (configurable) |

| Conveyor System | Mesh belt / Edge rail |

| Max PCB Width | Up to 500 mm (depending on configuration) |

| Temperature Control | Precision PID with real-time monitoring |

| Cooling System | Forced air / optional water cooling |

| Energy Efficiency | Low power consumption with heat recovery design |

| Reliability | Designed for continuous, high-volume production |

| Supplier Type | Wholesale SMT Equipment Supplier |

HELLER 1936 MK7 Solder Reflow Oven Wholesale Supplier

The HELLER 1936 MK7 Solder Reflow Oven delivers superior thermal performance, energy efficiency, and advanced process control. As a reliable wholesale supplier for SMT, we provide high-quality ovens engineered for precision, consistency, and maximum throughput in modern PCB assembly.