| Parameter | Mirage | Mirage-D |

|---|---|---|

| Model | Mirage | Mirage-D |

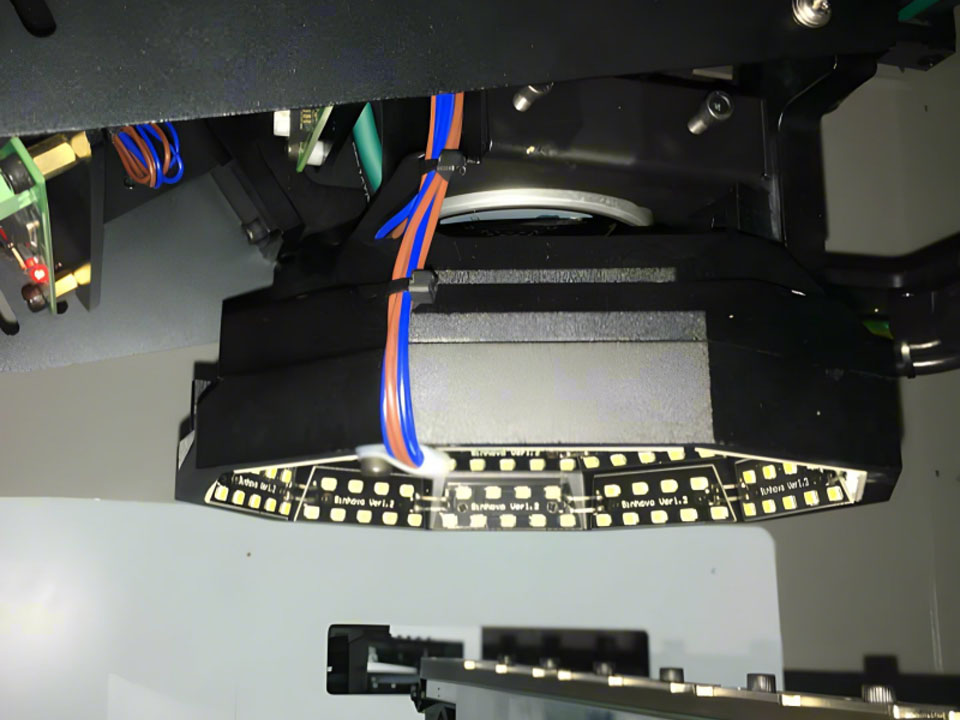

| Lighting System | RGB + White LED ring lighting | RGB + White LED ring lighting |

| Vision System | 3D two-direction digital projector | 3D two-direction digital projector |

| Camera | 4M / 12M industrial high-speed | 4M / 12M industrial high-speed |

| Resolution | 10µm – 15µm (adjustable) | 10µm – 15µm (adjustable) |

| Height Resolution | 1µm | 1µm |

| Product Size | W1080 × D1300 × H1850mm | W1083 × D1445 × H1800mm |

| Weight | 777 KG | 950 KG |

| FOV Size | 30.6 × 30.6mm (4M/15µm) | 40.9 × 30.7mm (12M/10µm) |

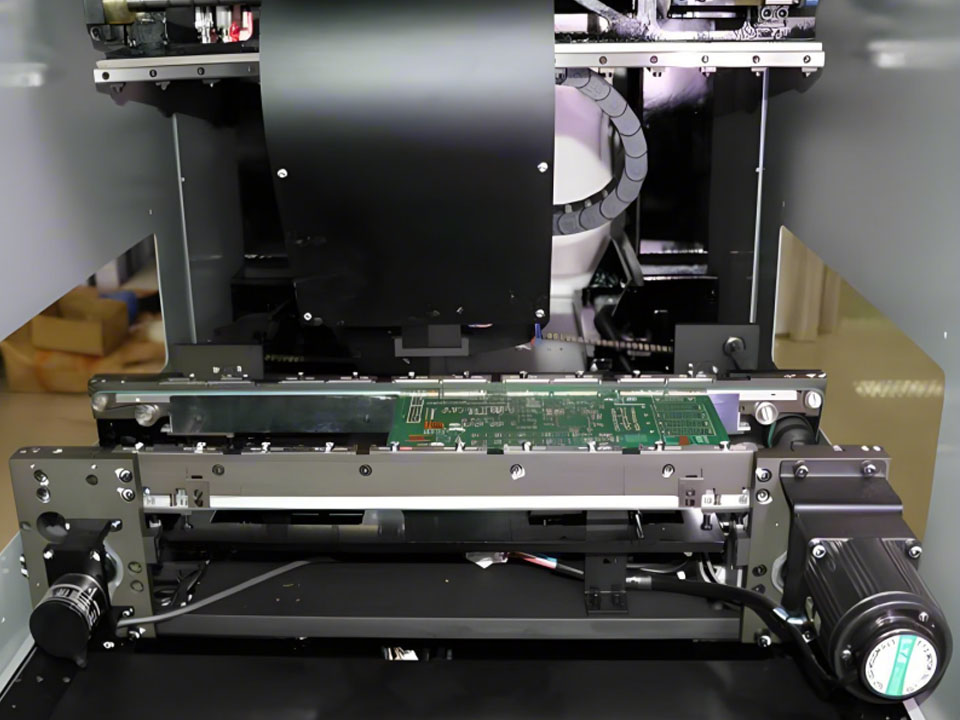

| PCB Size | 50 × 70mm – 510 × 460mm | Single lane: 50 × 70mm – 510 × 590mm Dual lanes: 50 × 70mm – 510 × 330mm |

| PCB Thickness | 0.6mm – 6mm | 0.6mm – 6mm |

| Warpage Compensation | ±3mm | ±3mm |

| Inspection Theory | 2D + 3D image data analysis | 2D + 3D image data analysis |

| Inspection Speed | 330ms / FOV (2D+3D) | 330ms / FOV (2D+3D) |

| Inspection Defects | Insufficient paste, excessive paste, bridging, shifting, no paste, shorts, icicles, shape defects | |

| Conveyor System | Bottom-up fix board clamping; Automatic loading/unloading; Auto rail width adjustment; SMEMA standard; Rail height: 900 ± 20mm | |

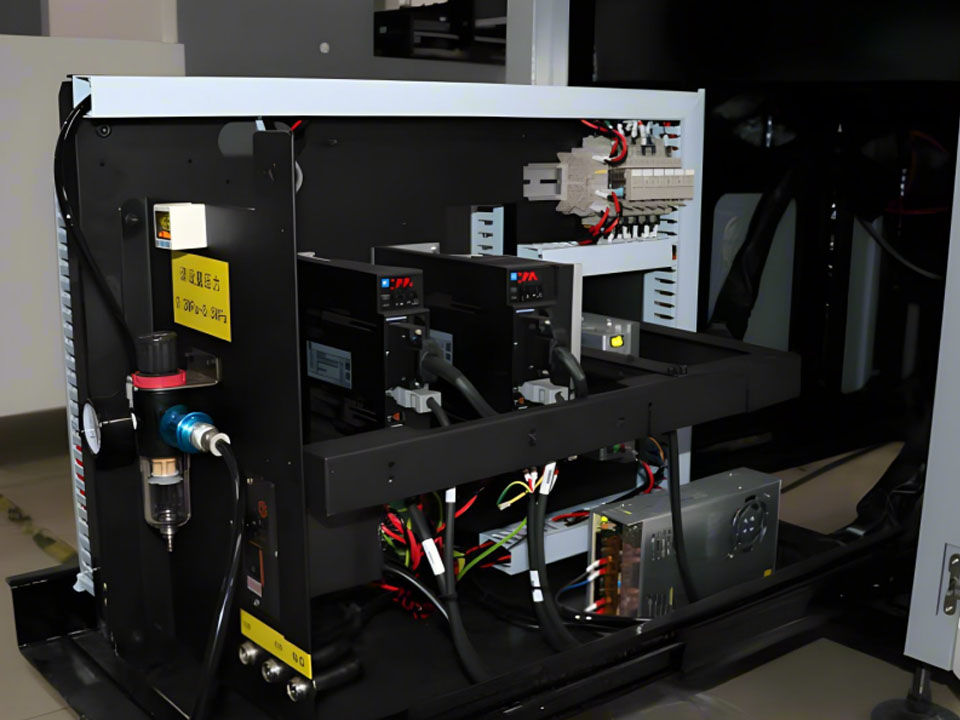

| Power Requirements | AC 220V, 50/60Hz, 1.8 KVA | AC 220V, 50/60Hz, 1.8 KVA |

| Air Requirements | 0.5 MPa | 0.5 MPa |

| Environment | Temp: 5–40℃; Humidity: 25%–80% RH | Temp: 5–40℃; Humidity: 25%–80% RH |

| Interfaces | SMEMA | SMEMA |

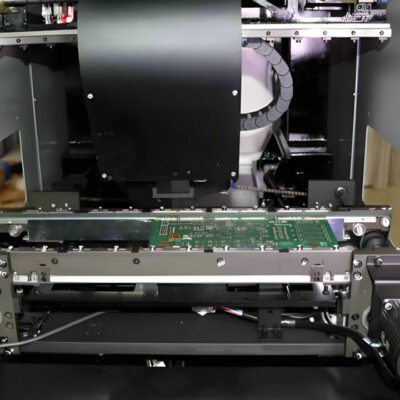

JUTZE Mirage 3D SPI OEM Manufacturer High-Precision System

JUTZE Mirage 3D SPI OEM Manufacturer High-Precision System delivers advanced solder paste inspection with dual 2D/3D imaging, RGB+White LED lighting, and high-speed cameras. Offering accurate detection of defects like bridging, voids, or insufficient paste, it ensures reliable PCB quality control with automated handling.