Features

| Feature | Description |

|---|---|

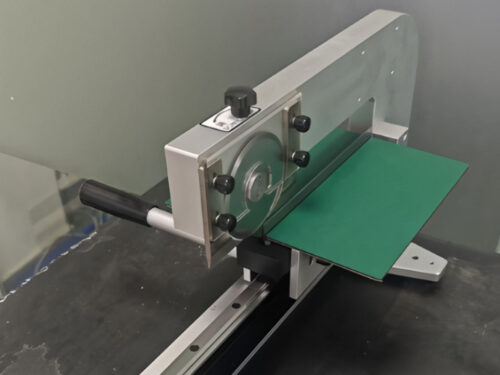

| Cutting Method | V-Groove PCB cutting |

| Cutting Speed | High-speed cutting for fast production |

| Cutting Precision | Accurate, clean cuts with minimal waste |

| Power Supply | 220V AC ± 10% |

| Control System | Automatic with PLC interface |

| Ease of Use | User-friendly interface with easy setup and operation |

| Versatile Application | Suitable for cutting various PCB sizes and thicknesses |

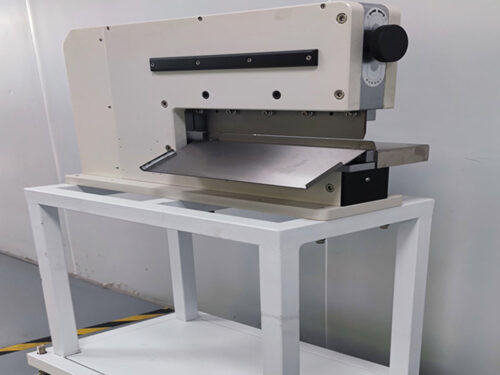

Specifications

| Specification | Value |

|---|---|

| Maximum PCB Size | 450 mm x 450 mm |

| Cutting Thickness | 0.2 mm – 5 mm |

| Cutting Speed | Adjustable up to 800 mm/min |

| Cutting Accuracy | ±0.1 mm |

| Blade Material | Tungsten carbide for durable, long-lasting performance |

| Machine Dimensions (L x W x H) | 1200 mm x 800 mm x 1200 mm |

| Weight | Approx. 500 kg |

| Operating Temperature | 10°C – 40°C |

| Operating Humidity | 30% – 85% |

| Noise Level | < 75 dB |

Key Benefits

- Precision Cutting: Achieves accurate, clean cuts with minimal waste for high-quality PCBs.

- Durability: Built with long-lasting materials, ensuring reliable performance over time.

- Efficiency: High-speed cutting maximizes productivity and minimizes downtime.

- Easy Operation: Simple controls and a user-friendly interface reduce training time.

- Flexible Applications: Supports various PCB sizes and thicknesses, ideal for diverse production needs.

Applications

- PCB Manufacturing: Essential for cutting PCBs after the assembly process in electronics production.

- Electronics Industry: Ideal for high-precision cutting in mobile, automotive, and consumer electronics manufacturing.

- High-Volume Production: Suitable for fast-paced environments where efficiency and accuracy are key.