Technology Overview

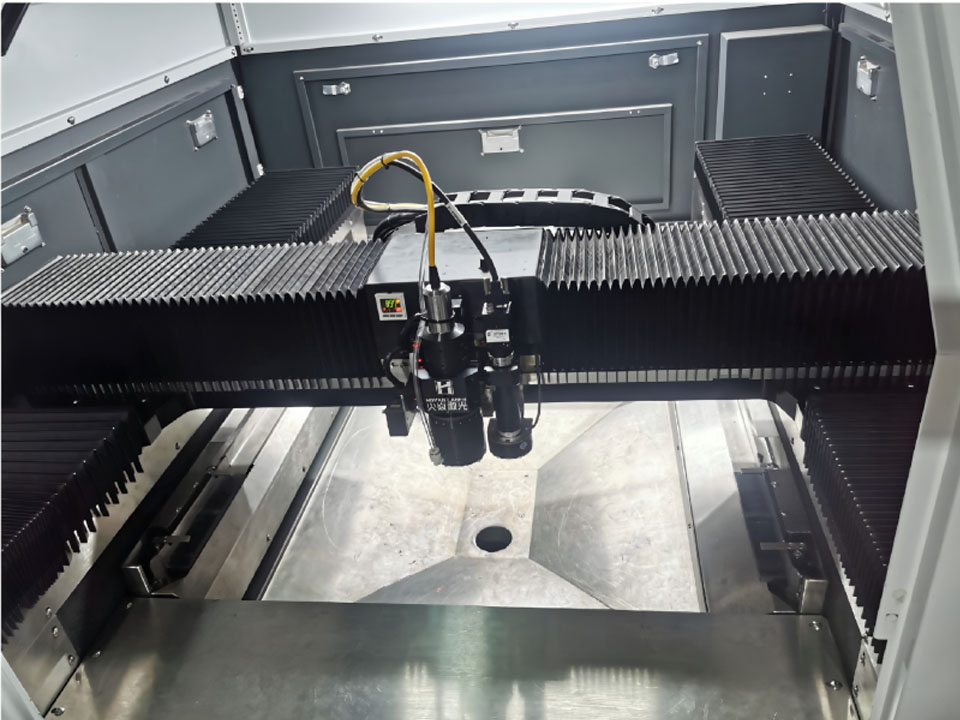

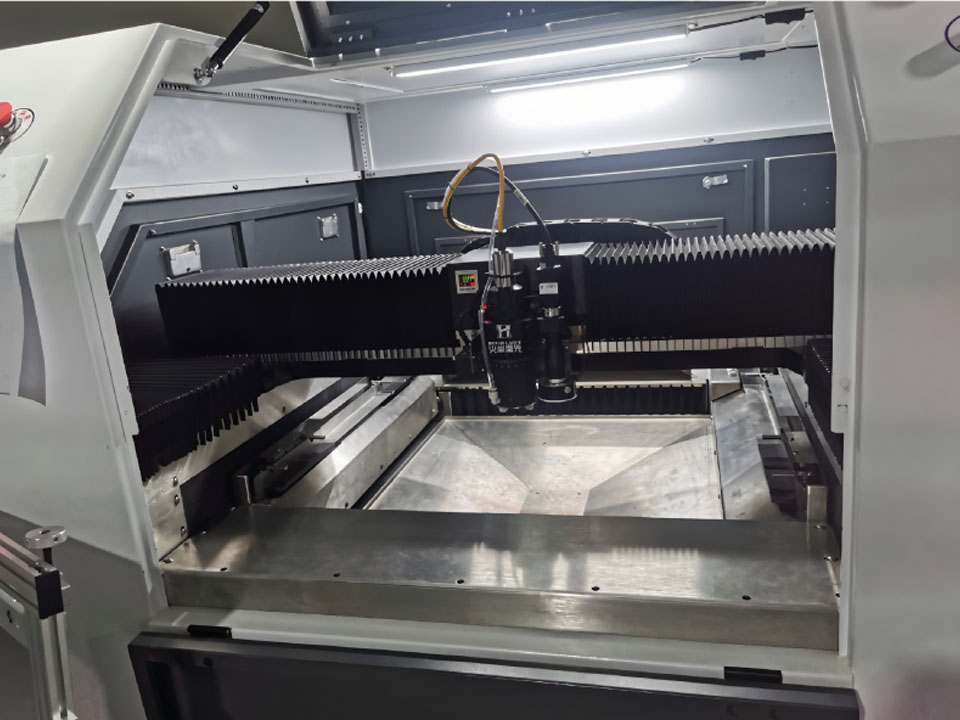

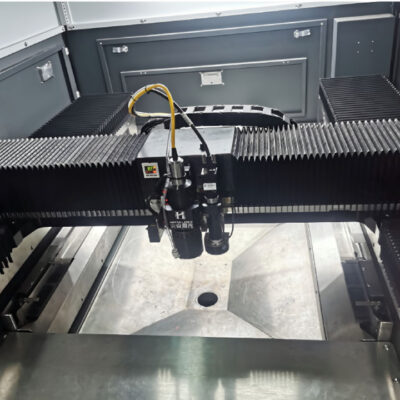

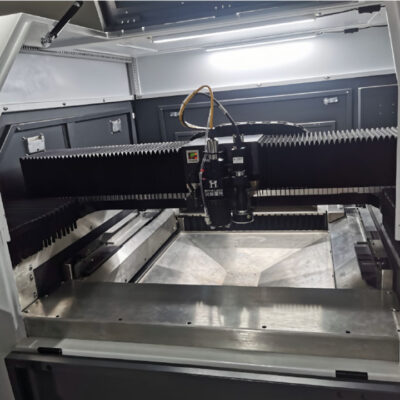

Laser cutting focuses a high-power density beam to rapidly heat material to vaporization, forming precise micro-holes and continuous slits. Combined with CNC and CAD/CAM software, it enables unlimited contour cutting, flexible trajectory modification, multi-part processing, and automated 3D curve cutting for advanced stencil manufacturing.

Specifications

| Parameter Category | MF-680PRO | MF-6080 | MF-6120 |

|---|---|---|---|

| Cutting Speed | 15,000–30,000 pads/h | 20,000–50,000 pads/h | 20,000–50,000 pads/h |

| Cutting Area | 680 × 680 mm | 600 × 680 mm | 600 × 1200 mm |

| Cutting Thickness | ≤ 0.5 mm | ≤ 0.5 mm | ≤ 0.5 mm |

| Cutting Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm |

| Laser | IPG Fiber Laser | IPG Fiber Laser | IPG Fiber Laser |

| Laser Power | 100W / 200W | 100W / 200W | 100W / 200W |

| Operating Software | HY CUT | HY CUT | HY CUT |

| Data Format | STC / DXF / GBR / LMD | STC / DXF / GBR / LMD | STC / DXF / GBR / LMD |

| Machine Body | Marble | Marble | Marble |

| Machine Size (mm) | 1550 × 1400 × 1550 | 1580 × 1420 × 1550 | 2080 × 1500 × 1550 |

| Mesh Frame Size | 740 × 1500 × 40 (MAX) | 740 × 1500 × 40 (MAX) | 740 × 1500 × 40 (MAX) |

| Stencil Sheet Size | 760 × 760 (MAX) | 900 × 600 (MAX) | 1320 × 600 (MAX) |

| Machine Weight | 2400 Kg | 2200 Kg | 3200 Kg |

| Input Power | AC220V / 2KW | AC220V / 2KW | AC220V / 2KW |

| Auxiliary Gas | O₂ / N₂ / Compressed Air | O₂ / N₂ / Compressed Air | O₂ / N₂ / Compressed Air |

| Gas Pressure | 0.6 – 1.5 MPa | 0.6 – 1.5 MPa | 0.6 – 1.5 MPa |

| Temperature | 22 ± 2 ℃ | 22 ± 2 ℃ | 22 ± 2 ℃ |

| Humidity | <60% | <60% | <60% |