| Parameter | Value |

|---|---|

| Model | MF-Q330 |

| Process type | Offline/inline PCB depaneling |

| Cutting method | High-speed router (tab-route); V-cut support |

| Work area | 330 × 330 mm |

| Max PCB size | 320 × 300 mm (typical) |

| PCB thickness | 0.4–4.0 mm |

| Component keep-out | Top ≤40 mm; Bottom ≤15 mm |

| Spindle speed | 60,000–100,000 rpm (programmable) |

| Router bit dia. | Ø0.8–3.2 mm |

| Positional accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Cycle time | 8–20 s per tab (layout dependent) |

| Vision alignment | Fiducial camera, auto correction (X/Y/θ) |

| Programming | CAD/Gerber import, point-and-click teach |

| Dust collection | Enclosed hood + external 2.2 kW vacuum, HEPA |

| Safety | Light curtain, door interlock, E-stop, leak detect |

| Interfaces | SMEMA, MES ready, Ethernet, barcode option |

| HMI/Control | 15″ touch panel, recipe library, alarms, logs |

| Conveyor height | 900 ± 20 mm; L→R / R→L selectable |

| Power supply | AC 380–415 V, 50/60 Hz, 3-phase |

| Total power | 6 kW (max) |

| Air supply | 0.5–0.7 MPa, ≥120 L/min |

| Noise level | ≤75 dB(A) |

| Dimensions (L×W×H) | 1200 × 1100 × 1550 mm |

| Net weight | ~650 kg |

| Options | Auto tool changer (6/8 slots), ionizer, inline kit, vacuum table, laser marker |

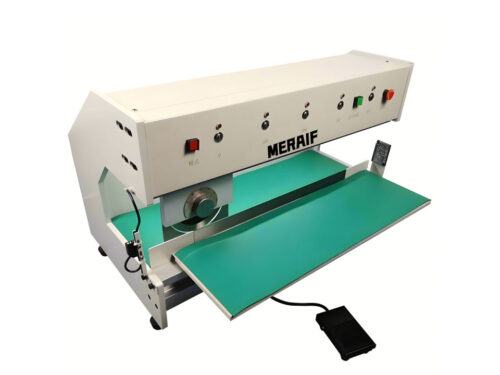

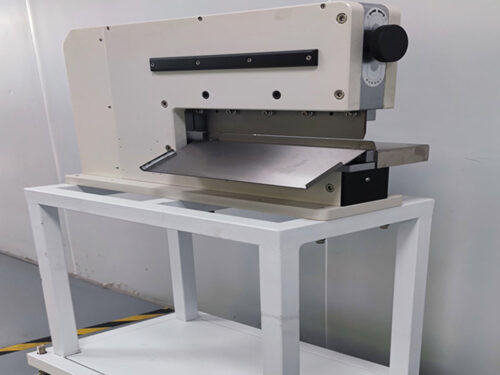

MF-Q330 PCB Cutting Machine Manufacturer High-Precision

MF-Q330 delivers high-precision PCB depaneling for SMT lines. Rigid servo gantry, vision fiducials, and low-stress routing protect components. Closed dust collection, ESD-safe frame, CAD/Gerber import, and quick recipe changeover drive quality, speed, and consistent yields. Inline/offline operation.