Overview

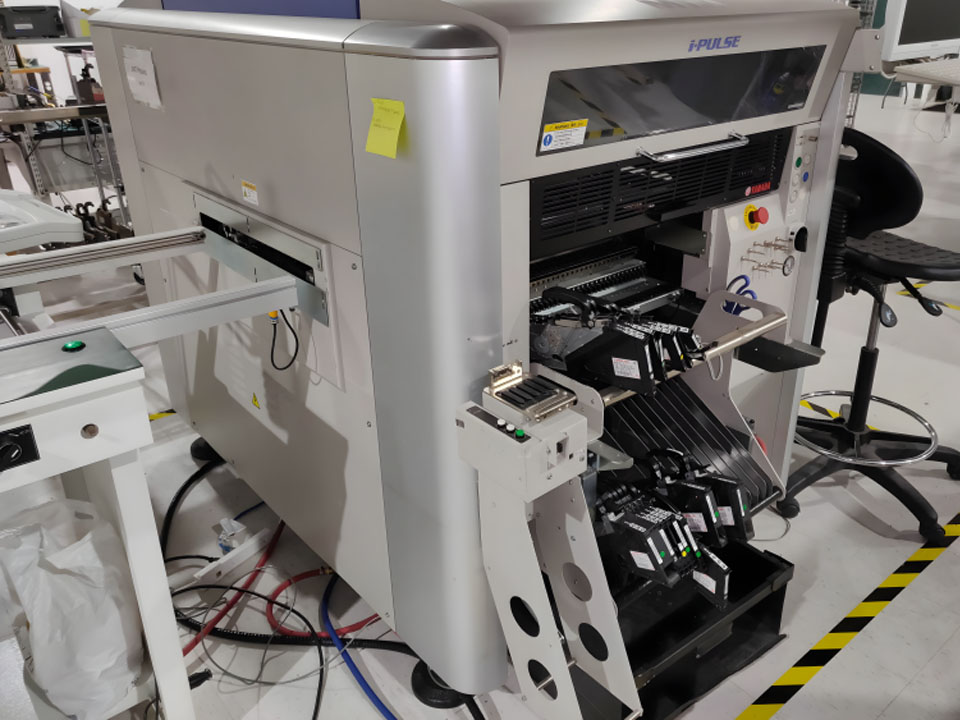

The I-Pulse M10 represents the next generation in compact SMT automation. It delivers the advanced features of a larger machine in a smaller footprint, making it an excellent complement to existing iPulse lines or a highly flexible standalone mounter. Its enhanced PCB and component handling capabilities offer production capacity previously unseen in its class.

Key Specifications

| Feature | Specification |

|---|---|

| Optimum Speed | 30,000 CPH (Components Per Hour) |

| Placement Accuracy | Chip: +/- 0.040mm IC: +/- 0.025mm |

| Feeder Platform | 72 positions (max) |

| Maximum PCB Size | L 740mm x W 510mm |

| Applicable Components | 01005 (0402mm) ~ 120mm x 90mm |

| Max Component Height | 30mm |

| Component Range | BGA, CSP, odd-form, connectors, etc. |

Features & Capabilities

- Flexible Head Configuration: Available in 4 and 6 head configurations to meet specific production needs.

- Interchangeable Feeder Banks: Supports a maximum of 72 fixed feeders or two changeable banks of 36 feeders for rapid changeover.

- Tray Compatibility: The rear feeder bank can be swapped with a 40-position tray changer for handling tray-fed parts.

- Force Control Function: A standard feature allowing precise adjustment and measurement of placement force from 5N to 60N.

- Placement Verification: Includes a standard downward-looking camera to verify component placement, reducing the need for separate inspection machines.