Summary

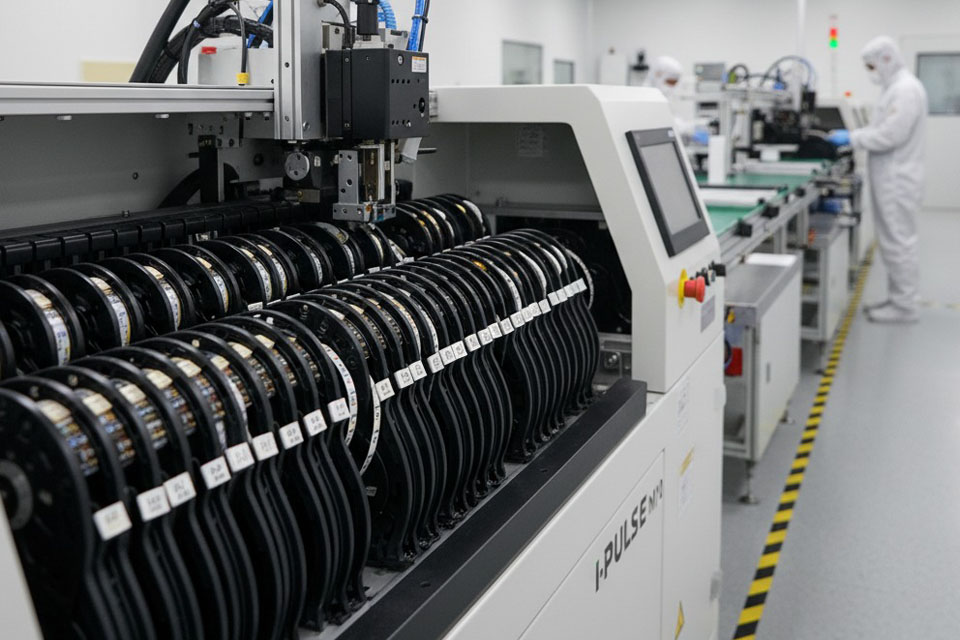

The Yamaha I-Pulse M10 pick and place machine is a highly advanced automated solution designed for electronic assembly, renowned for its speed, precision, and versatility. Engineered to meet the demands of modern manufacturing, the M10 excels in a variety of applications, including electronics production and automotive electronics, making it a valuable asset across multiple industries. Its notable capabilities, such as high-speed operation, advanced vision systems, and intelligent feeders, enhance production efficiency and reduce error rates, which are critical in today’s competitive market.

Table of Contents

The M10 is distinguished by its ability to handle an extensive range of components, from surface mount devices to irregular shapes, all while maintaining a remarkable placement accuracy of ±0.0005 inches. This level of precision is complemented by features that ensure consistent performance and reliability, thus fostering confidence in production quality and enabling manufacturers to adhere to stringent standards. Furthermore, the machine’s compact design optimizes floor space and minimizes maintenance requirements, allowing for seamless integration into existing workflows without heavy reliance on external support.

Notably, the Yamaha I-Pulse M10’s adaptability to changing market demands positions it as a key player in sectors experiencing rapid technological advancements, such as LED lighting and automotive electrification. As manufacturers increasingly seek to streamline operations and enhance productivity, the M10’s capabilities offer a competitive edge, facilitating swift responses to client specifications and market fluctuations. However, some controversies have arisen regarding the machine’s initial cost and the need for skilled operators to fully leverage its advanced features, raising discussions about return on investment and workforce training in the industry.

Overall, the Yamaha I-Pulse M10 pick and place machine stands out in the landscape of surface mount technology (SMT) equipment, combining cutting-edge performance features with comprehensive support services. Yamaha’s established reputation and commitment to innovation further enhance the M10’s appeal, making it a leading choice for businesses aiming to optimize their manufacturing processes and maintain high-quality standards in their production outputs.

Key Features

The Yamaha I-Pulse M10 pick and place machine is designed with a variety of standout features that enhance its performance and reliability in electronic assembly applications.

High-Speed Operation

One of the key attributes of the Yamaha M10 is its high-speed operation capability. The machine is equipped with a high-speed head that can handle a significant number of components per hour, thereby improving production efficiency and reducing cycle times.

Advanced Vision Systems

The M10 features sophisticated vision systems that enable precise alignment and verification of components during placement. These systems can detect and correct variations in component orientation, ensuring accurate placement, even for irregularly shaped components. The upgraded image-processing subsystem accelerates inspection cycle times by at least 60% and enhances resolution, allowing for the detection of minute defects.

Multi-Function Heads

The machine incorporates multi-function heads that can handle various component types, including surface mount devices (SMDs), through-hole components, and odd-shaped components. These heads come with interchangeable nozzles, allowing the M10 to accommodate different component sizes and perform additional functions like testing, dispensing, and inspection, thereby enhancing versatility.

Intelligent Feeders

Yamaha’s intelligent feeders provide an efficient supply of components. They can hold multiple component reels or trays and automatically feed the components to the pick and place heads. This system is equipped with sensors to monitor component availability, helping to prevent errors caused by empty feeders.

Precision and Accuracy

Precision is another significant feature of the M10. The machine can position components within 1/10,000th of an inch, achieving a placement accuracy that surpasses human assembly capabilities. This high level of accuracy minimizes defects and improves the overall quality of the final product.

Component Compatibility

The Yamaha M10 is compatible with a wide range of electronic components, including resistors, capacitors, integrated circuits (ICs), and connectors. This flexibility allows it to handle various package types, making it suitable for diverse manufacturing needs.

Maintenance and Calibration

Regular maintenance and calibration are essential for ensuring the machine’s optimal performance. Operators must perform calibration procedures for the vision system and pick and place heads, as well as regular inspections for wear and tear. Adhering to the manufacturer’s maintenance guidelines helps sustain the machine’s efficiency and longevity.

Operational Advantages

The Yamaha I-Pulse M10 pick-and-place machine offers several operational advantages that significantly enhance manufacturing processes. One of its key features is high efficiency, which leads to lower production costs over time. This efficiency is achieved through reduced error rates, making the machine a cost-effective solution for businesses striving to maximize their productivity and minimize waste.

Space Optimization

The compact design of the I-Pulse M10 allows it to operate within a relatively small area, freeing up additional space on the assembly line for employees and other equipment. By programming the machine to work within predetermined confines, manufacturers can improve the overall use of their assembly floor, facilitating a more organized and productive work environment.

Low Maintenance Requirements

Despite utilizing advanced technology, the I-Pulse M10 requires minimal maintenance, allowing companies to maintain operations without heavy reliance on external support. In-house maintenance can usually handle the upkeep, and necessary parts can often be sourced locally. This ease of maintenance contributes to uninterrupted production, as thorough upkeep prevents common issues such as misplacing components and operational inefficiencies.

Consistency and Precision

The I-Pulse M10 guarantees consistent performance through precise programming, ensuring that operations are executed with a high degree of accuracy. This precision is crucial in manufacturing, as it directly influences the quality of the end product. The machine’s ability to deliver reliable results repeatedly fosters confidence in production quality and helps manufacturers meet stringent standards.

Enhanced Productivity

Investing in the I-Pulse M10 allows companies to streamline their operations, ultimately providing a competitive edge in the market. The machine’s efficient programming capabilities minimize the need for frequent changeovers and human involvement, reducing production stops and the likelihood of errors. This automation enables skilled operators to focus on critical tasks that require human judgment, thereby enhancing overall productivity and operational effectiveness.

Applications and Industry Use Cases

Overview

The Yamaha I-Pulse M10 pick and place machine is designed to enhance manufacturing productivity across various industries. Its flexibility and advanced features make it suitable for applications ranging from high-volume consumer electronics to specialized industrial products. The machine is particularly advantageous for companies that require rapid adaptability to changing market demands and diverse product specifications.

Electronics Manufacturing

One of the primary applications of the I-Pulse M10 is in the electronics manufacturing sector, particularly in surface-mount technology (SMT) processes. The machine’s high-speed head enables it to handle a large number of components per hour, significantly improving production efficiency and reducing cycle times. This is especially critical in industries where time-to-market is a key competitive factor.

LED Lighting

The rise of LED technology has created substantial opportunities for electronics manufacturers, as evidenced by the experiences of companies like C-LED of Imola, Italy. This company has successfully leveraged the capabilities of the I-Pulse M10 to support advanced assembly processes essential for LED lighting applications, ensuring high-quality production while maintaining flexibility in manufacturing. Features such as board warp detection and the ability to handle components ranging from 01005 to larger sizes allow for a diverse range of LED products to be efficiently produced.

Automotive Industry

With the accelerating trend of automotive electrification, the I-Pulse M10 is increasingly used in the automotive electronics market, which is valued at over $270 billion. The machine’s adaptability to various component sizes and types enables manufacturers to meet the complex demands of modern automotive designs, which often require a mix of high-volume and low-mix production capabilities. Additionally, the incorporation of advanced technologies such as artificial intelligence in automotive applications benefits from the precision and speed of the I-Pulse M10.

Custom Manufacturing

The machine is also effective in custom manufacturing environments where unique and specialized products are developed. Its hybrid production capabilities allow for simultaneous mounting and dispensing processes, accommodating a range of materials and configurations. This versatility is crucial for companies that need to respond quickly to client specifications without sacrificing quality.

Case Studies

Various case studies highlight the effectiveness of the I-Pulse M10 in real-world applications. For instance, Yamaha Intelligent Machines collaborated with multiple manufacturing partners to improve assembly processes in sectors like industrial controls and medical devices. These partnerships showcase the machine’s role in enhancing quality and productivity across diverse applications.

Competitive Comparison

The Yamaha I-Pulse M10 pick and place machine stands out in the competitive landscape of surface mount technology (SMT) equipment due to several key advantages that enhance its performance and reliability compared to its competitors.

Performance Features

One of the critical performance features of the Yamaha I-Pulse M10 is its exceptional accuracy and placement speed. The machine boasts a linear encoder positioning system that provides an accuracy of ±0.0005″, which is among the best in the industry. This level of precision is crucial for producing high-quality circuit boards, making it a preferred choice for organizations that prioritize accuracy in their manufacturing processes. Additionally, the machine’s component placement speed varies to meet the needs of different production requirements, allowing businesses to tailor their operations to their specific demands.

Consistency and Reliability

The Yamaha I-Pulse M10 ensures consistency through its advanced programming, which enables the machine to deliver reliable performance regardless of external conditions such as production monotony or chaotic environments. This level of consistency not only enhances the quality of the outputs but also contributes to maximizing overall productivity in factories. As companies invest in the I-Pulse M10, they gain a competitive edge by significantly improving their operational efficiency and output quality.

Comprehensive Support and Services

In addition to its superior technological features, Yamaha offers comprehensive after-sale services that further enhance the value of the I-Pulse M10. This includes a two-year maintenance period during which any necessary repairs or replacements are provided at no additional cost, alongside free software upgrades and regular customer visits to gather feedback and ensure satisfaction. This commitment to customer service helps build long-term relationships and trust, giving Yamaha an edge over competitors who may not offer such extensive support.

Brand Reputation and Expertise

Yamaha’s established reputation in the market is another significant advantage. With over 15 years of experience in SMT manufacturing and a professional technical and sales team, Yamaha is recognized for its commitment to quality and innovation. The company’s integration of R&D, manufacturing, sales, and service allows for a comprehensive approach to customer needs, which is not always matched by competitors.